Methods for Improved Accuracy and Speed for Spot Scanning Systems

Background

A key benefit of pencil beam scanning particle therapy is high precision placement of dose. In the transverse plane this precision relies on a consistent incoming beam trajectory and predictable behaviour of the beam scan magnets. However the beam trajectory may vary, and effects like scan magnet yoke hysteresis, eddy currents and power supply bandwidth limitations can affect the spot positioning accuracy, stability, reproducibility and speed.

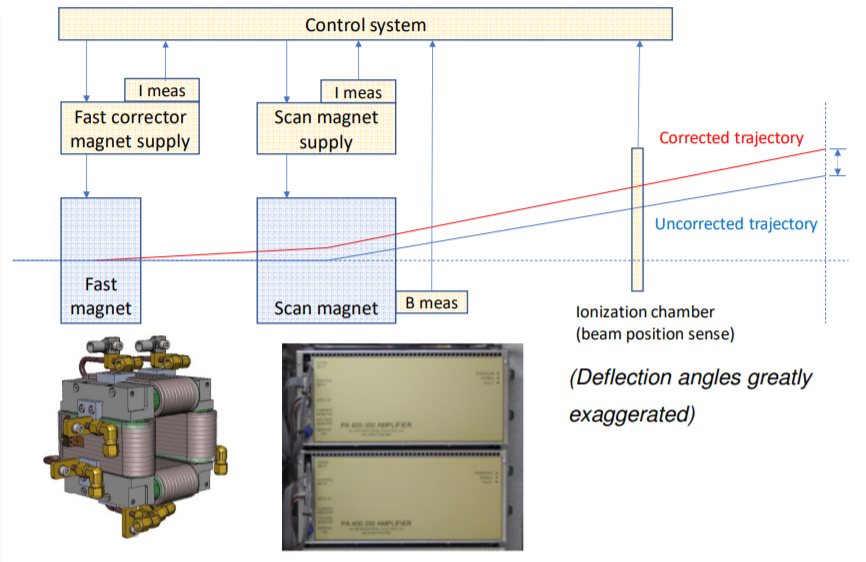

Fast corrector magnet for improving spot position accuracy

Several particle therapy facilities allow modulation of the scan magnet current while a spot is being delivered. This is most practical for with large scan magnet to isocentre spacing. We propose an alternative arrangement for proton therapy in which a small, fast correction magnet of deliberately small deflecting power is used in combination with the main scan magnets to provide an integrated system which approaches the ideal.

By limiting the deflection of the corrector to less than 5 mm at isocentre using a maximum gap field of 310 Gauss, the magnet can be physically small (10 cm pole length), highly linear and have very low inductance and resistance. The coil current supply can be conveniently integrated with the main scan magnet supplies, using the same DC bus and infrastructure.

The deflection of the combined system is the sum of the main magnet and correction magnet deflections to very good approximation. The correction magnet can be driven either using a pre-determined current profile or using feedback from main scan magnet fields or measured spot positions. The following can then be performed in real time:

- correction of small position errors due to hysteresis

- compensation of small drifts in position due to eddy current decay, beam trajectory change or power supply instability

- faster settling of position by compensating over or undershoot of the main field.

In addition to these features that improve the performance of the scan system, it is also possible to use the fast corrector to introduce deliberate blurring of a beam spot to increase its effective size upon demand and thus reduce the number of spots needed.

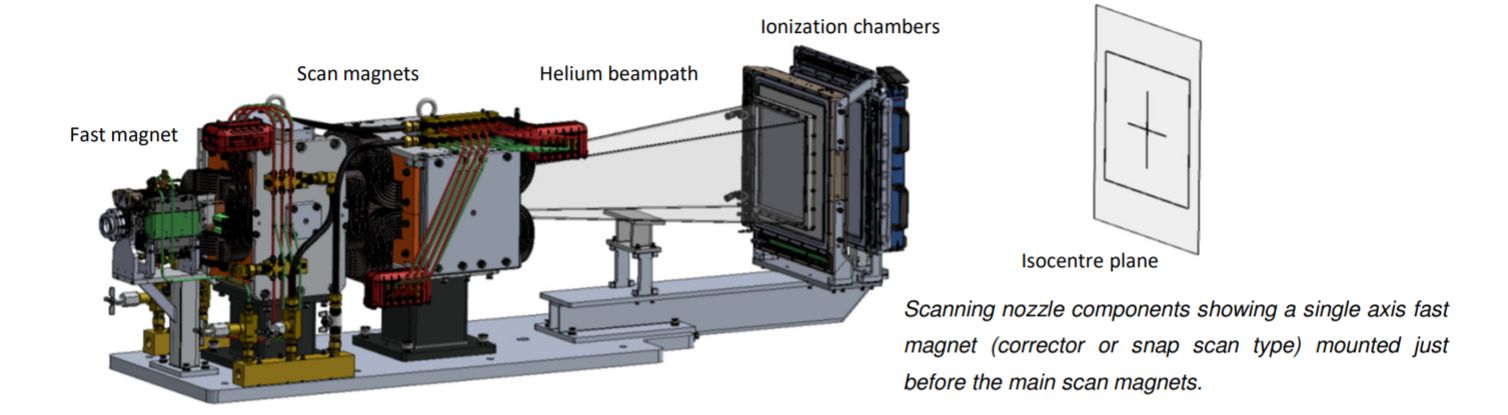

Control scheme (one axis shown) and a two-axis MN60 ferrite corrector magnet with pole length 10 cm, pole gaps 7 cm, calculated self inductance 76 µH and resistance 10 mΩ per axis. Deflection angle for 230 MeV protons is 2.2 mrad. The magnet is designed to be powered by one IECO PA400-350 four-quadrant supply per axis with current control bandwidth >10 kHz, DC current up to 140 A, voltage compliance 350 V.

Snap Scan magnet for improving spot delivery rate

An extension of the fast correction magnet concept allows a direct role in spot delivery. If the maximum deflection at isocentre is doubled to around 8 to 10 mm (at maximum energy), then the fast magnet can make most spot position changes on its own, in less than 50 µsec. While the dose is being delivered the main scan magnet then makes the same move (more slowly) but is exactly compensated by simultaneous reduction of the snap scan magnet field so that the beam spot does not move. Further control of the fast magnet in correction mode can negate position instabilities resulting from the beam turn-on.

The higher deflection is easy to achieve with the same power supply and magnet length if the design is optimized for a single bending direction, by reducing the pole gap. Pencil beam dose delivery maps typically arrange the spots in each isoenergy layer such that most moves are made by the faster axis to minimise the overall deadtime. Thus by speeding up the faster axis the dose delivery time is reduced.

Sales & Technical Enquiries:

sales@ptcusa.comService & Returns:

support@ptcusa.comMedia & Others:

contact@ptcusa.com© 2026 Pyramid Technical Consultants, Inc