Ionization Chamber Advances

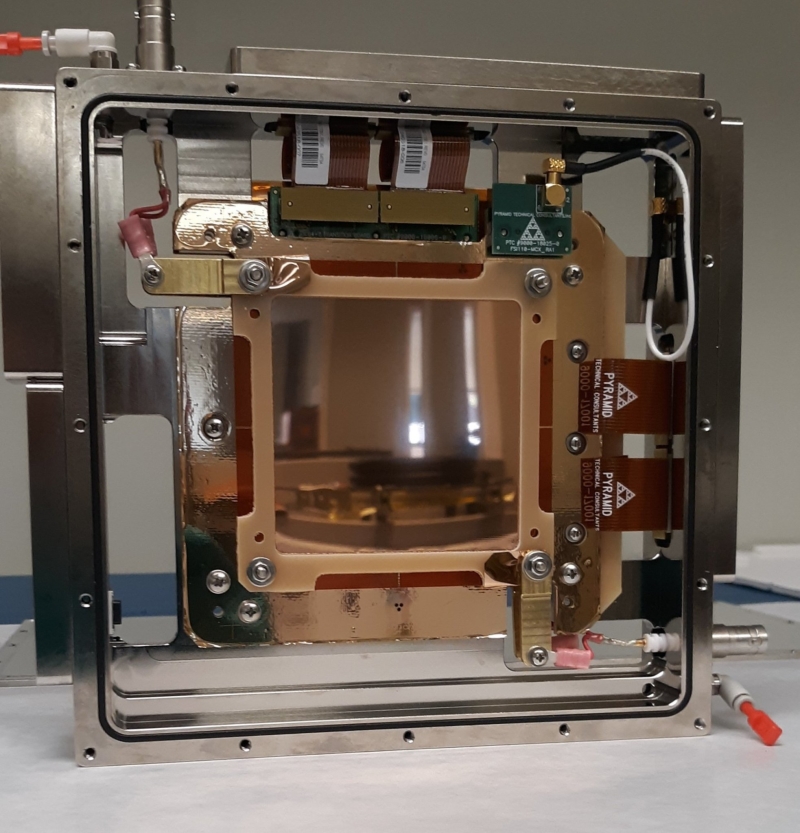

Pyramid continues to advance the performance and reliability of its ionization chamber products. Pyramid engineer Nick Dart, working in the ionization chamber assembly and test lab, has provided details of a new build of the flash therapy optimized IC64-6 chamber that demonstrates advances in gold coating, laser patterning and connection methods. The new chamber is showing good performance and stability in in-house testing and will be demonstrated on a proton system at an early opportunity.

The new gold electrodes provide:

- More precise and very consistent pattern writing

- Improved long term connection reliability

- Excellent high voltage stability

Following tests on the IC64-6, the new methods will be implemented on other chambers including the larger area IC128-25 models.

Related Products

Latest News

Sales & Technical Enquiries:

sales@ptcusa.comService & Returns:

support@ptcusa.comMedia & Others:

contact@ptcusa.com© 2025 Pyramid Technical Consultants, Inc